Energy - Digital pre-engineering cycle

More connected than ever, factories have entered the digital age. Internet of Things, artificial intelligence, cloud, big data... industry is undergoing a revolution!

Industry 4.0 will function with connected machines that will be able to know the object's production history and final demand in order to respond perfectly and independently. These connected objects also become capable of interacting with their environment.

Machines communicate with each other and adapt to demand in real time. They are also able to contact a specialist in the event of a breakdown, who can then analyze the problem remotely using augmented reality glasses, for example - a real time and money saver for the company.

IoT systems and communicating objects are invading our environment and revolutionizing our daily lives. Connected systems are at the heart of innovations linked to smart grids (for efficient energy management), smart buildings (for efficient building supervision), smart cities (for coordinated citizen services) and smart industry (for more efficient production organization).

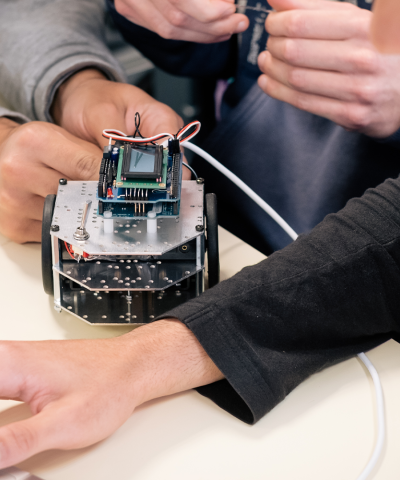

The engineers we train in the fields of digital manufacturing, networks, IoT, automation and robotics are at the heart of the challenges and developments facing our society.

While the UniLaSalle - ESIEE-Amiens engineering program offers the greatest opportunities in the digital sector, other UniLaSalle programs approach digital technology through its agricultural applications (Bachelor of Science and Engineering in Agriculture, Digital and Embedded Technologies) and geological applications (Digital Geology option within the Geosciences and Environment engineering program).